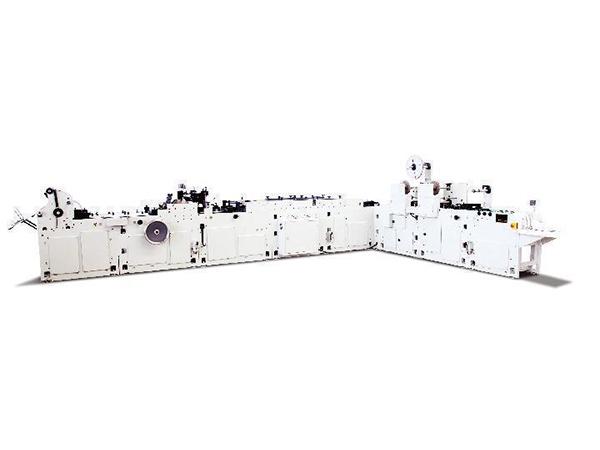

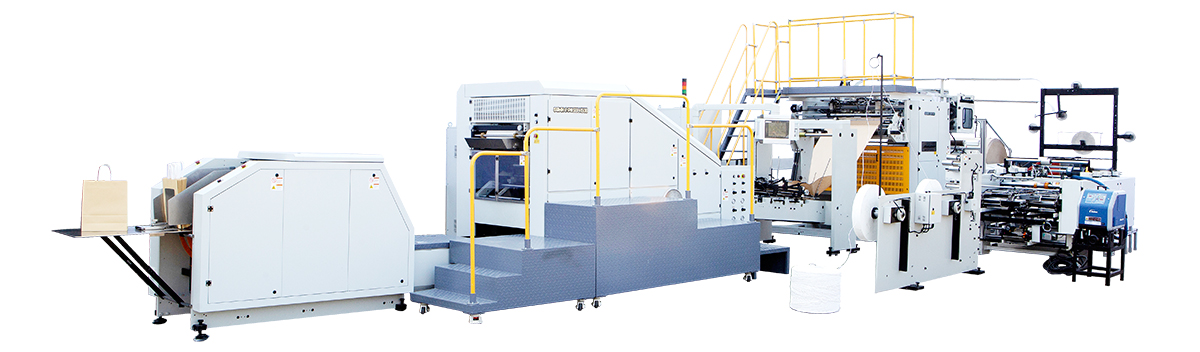

SBH330B/450B-HD Fully Automatic Roll Fed Twisted Handle Paper Bag Machine

This machine is designed to manufacture square bottom paper bags with a twisted handle from paper roll, paper patch roll and paper rope. By implementing handle making, handle application, tube forming, tube cutting, and bottom forming with a fully automatic process, this machine is especially suited to producing bags for food packaging, clothing and luxury branding products. That is especially suitable for foodstuff, clothing and luxury branding products.

-

Model:

SBH150B-2HD - Paper Thickness (gsm):

- 40-150

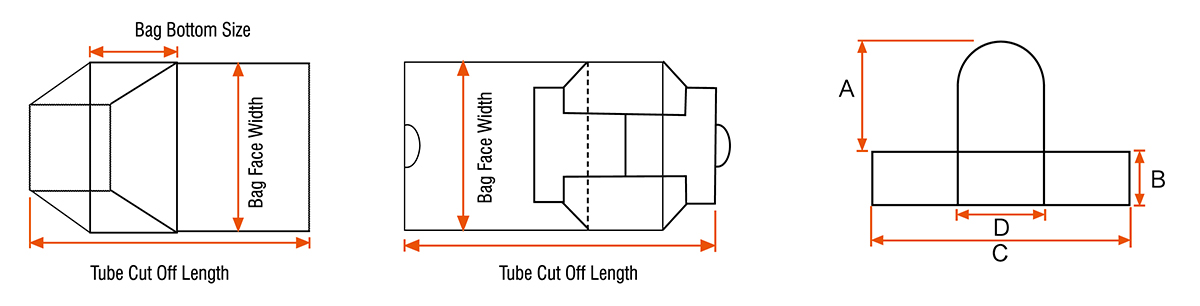

- Tube Cut Off Length (mm):

- 191-320/191-430(★)

- Bag Face Width (mm):

- 120-200/80-200(★)

- Bag Bottom Size (mm):

- 45-100

- Max. Speed (bags/min):

- 150

-

Model:

SBH330-2HD - Paper Thickness (gsm):

- 45-180

- Tube Cut Off Length (mm):

- 280-430/280-540(★)

- Bag Face Width (mm):

- 120-330/120-330(★)

- Bag Bottom Size (mm):

- 70-150

- Max. Speed (bags/min):

- 150

-

Model:

SBH330-5HD - Paper Thickness (gsm):

- 45-180

- Tube Cut Off Length (mm):

- 280-430/280-540(★)

- Bag Face Width (mm):

- 180-330/120-330(★)

- Bag Bottom Size (mm):

- 70-150

- Max. Speed (bags/min):

- 150

-

Model:

SBH330B-5HD - Paper Thickness (gsm):

- 50-180

- Tube Cut Off Length (mm):

- 280-430/280-50(★)

- Bag Face Width (mm):

- 180-330/150-330(★)

- Bag Bottom Size (mm):

- 70-180

- Max. Speed (bags/min):

- 150

-

Model:

SBH330BPro-5HD - Paper Thickness (gsm):

- 50-180

- Tube Cut Off Length (mm):

- 280-430/280-530(★)

- Bag Face Width (mm):

- 180-330/150-330(★)

- Bag Bottom Size (mm):

- 90-180

- Max. Speed (bags/min):

- 150

-

Model:

SBH450B-5HD - Paper Thickness (gsm):

- 70-180

- Tube Cut Off Length (mm):

- 380-640/368-762(★)

- Bag Face Width (mm):

- 230-450/200-450(★)

- Bag Bottom Size (mm):

- 90-205

- Max. Speed (bags/min):

- 120

-

Model:

SBH450B-6HD - Paper Thickness (gsm):

- 70-180

- Tube Cut Off Length (mm):

- 380-640/368-762(★)

- Bag Face Width (mm):

- 230-450/200-450(★)

- Bag Bottom Size (mm):

- 90-205

- Max. Speed (bags/min):

- 120

-

Model:

SBH450C-5HD - Paper Thickness (gsm):

- 70-180

- Tube Cut Off Length (mm):

- 380-640/368-762(★)

- Bag Face Width (mm):

- 230-450/200-450(★)

- Bag Bottom Size (mm):

- 120-260

- Max. Speed (bags/min):

- 120

-

Model:

SBH450C-6HD - Paper Thickness (gsm):

- 80-180

- Tube Cut Off Length (mm):

- 380-640/368-762(★)

- Bag Face Width (mm):

- 230-450/200-450(★)

- Bag Bottom Size (mm):

- 120-260

- Max. Speed (bags/min):

- 120

| Technical Info |

|

|

|

|

|

|

|

|

|

| Paper Roll Width (mm) | 420-640 | 430-1050 | 550-1050 | 550-1050 | 570-1050 | 670-1310 | 670-1310 | 730-1310 | 730-1310 |

| 280-640(★) | 405-1050(★) | 405-1050(★) | 465-1050(★) | 505-1050(★) | 610-1310(★) | 610-1310(★) | 690-1310(★) | 690-1310(★) | |

| Paper Roll Dia. (mm) | ≤1500 | ≤1500 | ≤1500 | ≤1500 | ≤1500 | ≤1500 | ≤1500 | ≤1500 | ≤1500 |

| Paper Roll Core Dia. (mm) | Φ76 | Φ76 | Φ76 | Φ76 | Φ76 | Φ76 | Φ76 | Φ76 | Φ76 |

| Paper Thickness (gsm) | 40-150 | 45-180 | 45-180 | 50-180 | 50-180 | 70-180 | 70-180 | 70-180 | 80-180 |

| Tube Cut Off Length (mm) | 191-320 | 280-430 | 280-430 | 280-430 | 280-430 | 380-640 | 380-640 | 380-640 | 380-640 |

| 191-430(★) | 280-540(★) | 280-540(★) | 280-540(★) | 280-540(★) | 368-762(★) | 368-762(★) | 368-762(★) | 368-762(★) | |

| Bag Face Width (mm) | 120-200 | 120-330 | 180-330 | 180-330 | 180-330 | 230-450 | 230-450 | 230-450 | 230-450 |

| 80-200(★) | 120-330(★) | 120-330(★) | 150-330(★) | 150-330(★) | 200-450(★) | 200-450(★) | 200-450(★) | 200-450(★) | |

| Bag Bottom Size (mm) | 45-100 | 70-150 | 70-150 | 70-180 | 90-180 | 90-205 | 90-205 | 120-260 | 120-260 |

| Handle Rope Height (A)(mm) | 102/115/125 | 102/115/125/140 | 102/115/125/140 | 102/115/125/140 | 102/115/125/140 | 102/115/125/140 | 115/125/140/150 | 102/115/125/140 | 115/125/140/150 |

| Handle Patching Length (C)(mm) | 95.25 | 95.25 | 152.4 | 152.4 | 152.4 | 152.4 | 190.5 | 152.4 | 190.5 |

| Handle Patching Width (B)(mm) | 40-50 | 40-50 | 40-50 | 40-50 | 40-50 | 40-50 | 40-50 | 40-50 | 40-50 |

| Rope Pitch (D)(mm) | 47.6 | 47.6 | 76 | 76 | 76 | 76 | 95 | 76 | 95 |

| Handle Rope Diameter (mm) | Φ3-4.5 | Φ3-4.5 | Φ3-4.5 | Φ3-4.5 | Φ3-4.5 | Φ3-4.5 | Φ3-4.5 | Φ3-4.5 | Φ3-4.5 |

| Handle Paper Patch Roll Diameter(mm) | Φ1200 | Φ1200 | Φ1200 | Φ1200 | Φ1200 | Φ1200 | Φ1200 | Φ1200 | Φ1200 |

| Handle Paper Patch Roll Width(mm) | 80-100 | 80-100 | 80-100 | 80-100 | 80-100 | 80-100 | 80-100 | 80-100 | 80-100 |

| Handle Paper Patch Thickness (gsm) | 90-135 | 90-135 | 90-135 | 90-135 | 90-135 | 90-135 | 90-135 | 90-135 | 90-135 |

| Max. Speed (bags/min) | 150 | 150 | 150 | 150 | 150 | 120 | 120 | 120 | 120 |

| Total Power (kW) | 24.5 | 30.5 | 30.5 | 31.32 | 31.32 | 33.22 | 33.22 | 33.22 | 33.22 |

| Machine Weight (kg) | about 13000 | about 16000 | about 16000 | about 16000 | about 16000 | about 18000 | about 18000 | about 18000 | about 18000 |

| Machine Size (L×W×H)(m) | 12×5.5×2.5 | 13.6×6×2.5 | 13.6×6×2.5 | 13.6×6×2.5 | 13.6×6×2.5 | 14.8×6×2.5 | 14.8×6×2.5 | 14.8×6×2.5 | 14.8×6×2.5 |

| Three Types of Bottom Seal | yes | yes | yes | yes | yes | yes (Two) | yes (Two) | yes (Two) | yes (Two) |

| Servo Lip Cut Device | yes | yes | yes | yes | yes | option | option | option | option |

| 1-4 Colors Flexo Printer Unit | yes | yes | yes | yes | yes | yes | yes | yes | yes |

| Servo Patch Unit | yes | yes | yes | yes | yes | yes | yes | yes | yes |

Note: "★" stands for No Handle.

- The servo adjustable former automatically adjusts the face width & gusset size, significantly reducing the debugging time.

- The drum is equipped with a vacuum assist for better control during bag bottom formation.

- The bag making machine is equipped with a Mitsubishi electric control system and Mitsubishi motion controller (CPU) in order to achieve a high speed and high precision, as well as motion control and a production flow test. With a touch screen display, the operation functions are clear.

- Equipped with a German BST automatic WEB guiding system, this machine can reduce waste and improve efficiency.

- This model is equipped with an American NORDSON cold glue adhesive system for bag side seal. The glue volume is automatically adjusted, as is the operation speed. As the system will recycle glue and clean itself automatically, there is no glue wasted.

- The handle making unit combines an American NORDSON cold glue system and NORDSON hot glue system, ensuring production is more economical and efficient.

- It is also equipped with an automatic lubricating oil system.